Professor Carl Frick, department head of the mechanical engineering department at the University of Wyoming, is the co-founder of Impressio Inc., a business that has recently risen to fame due to winning the category of player safety in the NFL’s innovation competition, the 1st and Future Pitch Competition.

For the competition, companies created different pitches about products that may benefit the NFL in terms of safety and player performance.

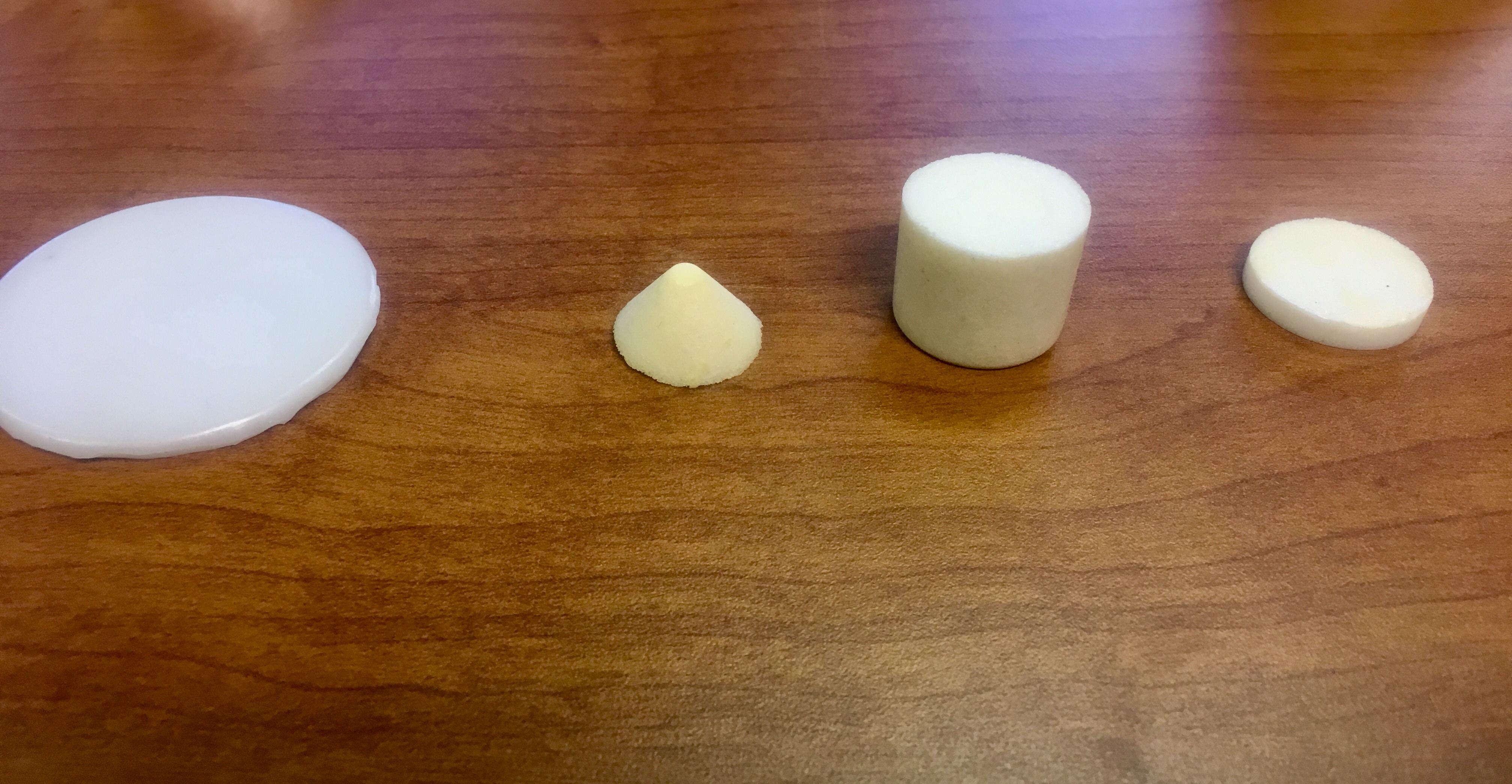

Impressio Inc. pitched the usage of the liquid crystal elastomers, known as LCEs, being studied by the mechanical engineering department at UW. LCEs are a polymer that can readily absorb heavy impact. The LCE that Impressio brought to the competition was a porous LCE, one with a more cushion-like texture that would go into the padding of the football helmets; helping to prevent the massive amounts of concussions that happen in the NFL each season.

“In this season, I think there was something around 250 concussions and with the help of the LCEs, we can reduce this number by a lot,” Viren Patel, undergraduate research assistant of Frick’s team, said.

Frick’s team of mechanical engineering students spent the past year and a half studying the LCE’s unique properties. Elastomer, after being deformed, can return to its original shape like rubber. This type of elasticity, combined with the high-impact resistance property of the LCEs allows for less damage to be done to football players’ heads in case of heavy impact during a game.

One of the Ph.D students involved in the LCE research, Dan Markel, described the effect in a real-world context.

“If we dropped your phone on the floor, it would probably be fine,” Markel said. “It might crack the screen, maybe, but the electronics would be fine. It might damage the glass components, but the vibration dampeners [prevent the electronics from breaking]. All of the [electronic] components are rigid, which means if you drop them, they’re going to shatter.”

The LCE has many different forms and depending on what a person does to alter the shape and texture of the LCE, it can serve different purposes. A plastic-like texture and a porous cushion-like texture could both be made from LCEs. This allows for more and more options for head safety innovation in helmet manufacturing companies, using the LCE material.

“They have helmets that are pretty advanced for other sports as well, like motocross,” Frick said. “They have pretty advanced helmets for absorbing impact as well and they have very specific needs for each one of those sports and activities. They’ve incorporated a new design, an emerging design and what’s nice about our material is that it’s appropriate for any one of those designs.”